Technological advances are used to improve the thermal and acoustic performance of homes. There is a wide choice between VIP (Vacuum Insulation Panels) and aerogels. Not to mention thin insulators, which, without being new, are far from conventional insulators. Buildingpros.net introduces you to these materials.

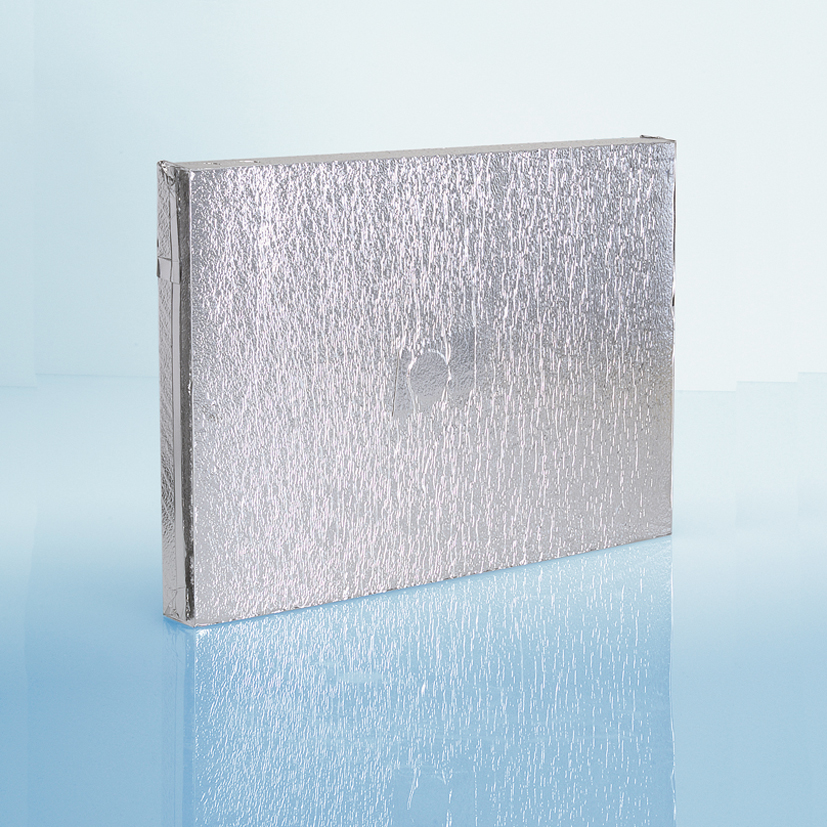

Vacuum Insulation Panels (VIP)

Ultra-thin, VIP (Vacuum Insulation Panels) are made of a “core” material, very rigid, confined in a waterproof film, and placed in a vacuum. Despite being extremely efficient, they are still not very widespread because of their high price. Let’s take an overview of this insulator.

VIP – The Thermal and Acoustic Performance

The VIP new generation insulation offers exceptional thermal capacities. Its thermal conductivity coefficient is between 0.0042 and 0.0050 W/m.K. In practical terms, 1 cm of VIP is equivalent to 6 cm of expanded polystyrene or 9 cm of mineral wool.

In terms of noise, its qualities are still poorly studied, but since the “core” material of the insulation consists of aerogels, it has an excellent capacity to reduce noise pollution.

Conditions for Installing Vacuum Insulation Panels (VIPs)

Vacuum insulation panels must be installed in two cross-layered layers with staggered joints to avoid thermal bridges caused by the edge to edge.

– The main disadvantage of this material is its fragility: it must not be pierced; otherwise, it loses its high qualities.

– The panels cannot be cut, so be sure to know the precise measurements of the surfaces to be treated.

– VIP is suitable for perfectly flat surfaces.

– Very efficient, VIP requires a low thickness. It can thus be sufficient in 30 mm, which makes it particularly interesting to save space indoors or during renovation work.

Longevity of VIPs

– VIPs are permeable to water vapor, but the installation of a vapor barrier is recommended.

– They have good compressive strength.

– The installation of simple protective plasterboards will allow the VIP to be kept away from holes and borings.

Price of Vacuum Insulation Panels

Still rare on the market, produced in smaller quantities than mineral wool, VIP is an expensive insulator: between 40 and 60 dollars per m².

But its performance is excellent, so the heating savings achieved with such insulation must be weighed against the savings.

Aerogels

Aerogels are the result of nanotechnology and have amazing insulating properties.

Made up of 99.8% air, they are incredibly light and closer to the appearance of a dust cloud than a conventional insulating material!

Their thermal and sound capacities are unbeatable; however, aerogels remain difficult to access for private individuals as they are offered at high prices to mostly big construction companies.

Aerogel: The Thermal and Acoustic Performance

Aerogels have an excellent thermal conductivity coefficient, the lowest for a solid: between 0.011 and 0.013 W/m.K.

The aerogel almost completely stops all modes of heat transmission. By way of comparison, it is 3 times more insulating than glass wool.

The efficiency is also real in terms of sound, with high-performance levels.

Aerogel Installation Conditions

Aerogels are challenging to produce and are still limited to industrial or construction uses.

Transparent, ultra-light, and resistant, it would be an excellent solution for home insulation if its price were not so high.

– A textile impregnation solution has been developed for ease of use: it is flexible and can be cut.

– It is considered non-toxic to health but requires protective equipment (goggles, mask, gloves) for added safety.

Aerogel Durability

Aerogels resist temperatures of 200°C and disintegrate after 1200°C.

– Permeable to water vapor, they can be combined with a vapor barrier.

– Flexible, they resist compression and support 2,000 times their weight.

Aerogel Prices

The main handicap of this type of insulation: the manufacturing cost of one kilogram is $1,800…

But techniques are being studied that will undoubtedly reduce this cost (and therefore the purchase price) within a few years.

The Reflective Insulating Paint

Insulating paint is a reflective paint process from space research. It can be used to insulate facades and interior walls, as well as roofs. Given its thinness, it is more of a thermal corrector than real insulation. But it can bring a little extra when you can’t use conventional insulation.

Reflective Insulating Paint: An Innovation in Thermal Insulation!

The insulating paint was developed for spatial use due to its low thickness. Initially used on space shuttles, it is now available for sale to private individuals.

Insulating paint is used to insulate interior walls, facades, and even roofs.

The above was Part 1 of an overview of the new generation of insulators on the market. Although they are not always available to the general public because of the price, they are among the latest trend in the building and construction industry. Discover even more types of insulators and those that are affordable in Part 2 of this topic.